Are you a medical device manufacturer looking to stay ahead in the industry? The CE mark is of utmost importance in the European market, and understanding its intricacies is crucial for success. In this fast-paced and highly regulated industry, keeping up with the latest requirements and standards can be a challenge. That’s where we come in. Our team of experts specializes in helping medical device companies navigate the complex world of CE marking. From understanding the regulatory landscape to ensuring compliance with the latest directives, we have the knowledge and experience to guide you through the process. In this article, we will explore everything you need to know about the CE mark for medical devices. So, let’s dive in and equip you with the essential information to stay ahead in this competitive industry.

Why is the CE mark important for medical device manufacturers?

The CE mark is a certification that indicates a medical device meets the requirements of the European Union’s Medical Device Directive (MDD) or the new Medical Device Regulation (MDR). This mark is essential for manufacturers who want to sell their products in the European Economic Area (EEA). Without the CE mark, it is illegal to market or distribute medical devices within the EEA.

The CE mark demonstrates that a medical device meets the necessary safety, health, and environmental protection requirements. It ensures that the device has undergone a conformity assessment procedure and has been deemed to conform with the applicable standards. The mark provides assurance to healthcare professionals and patients that the device is safe and effective for use.

The CE mark also allows manufacturers to access a large and lucrative market. With over 500 million people residing in the EEA, the region presents significant opportunities for medical device companies. By obtaining the CE mark, manufacturers can expand their customer base and increase their revenue potential.

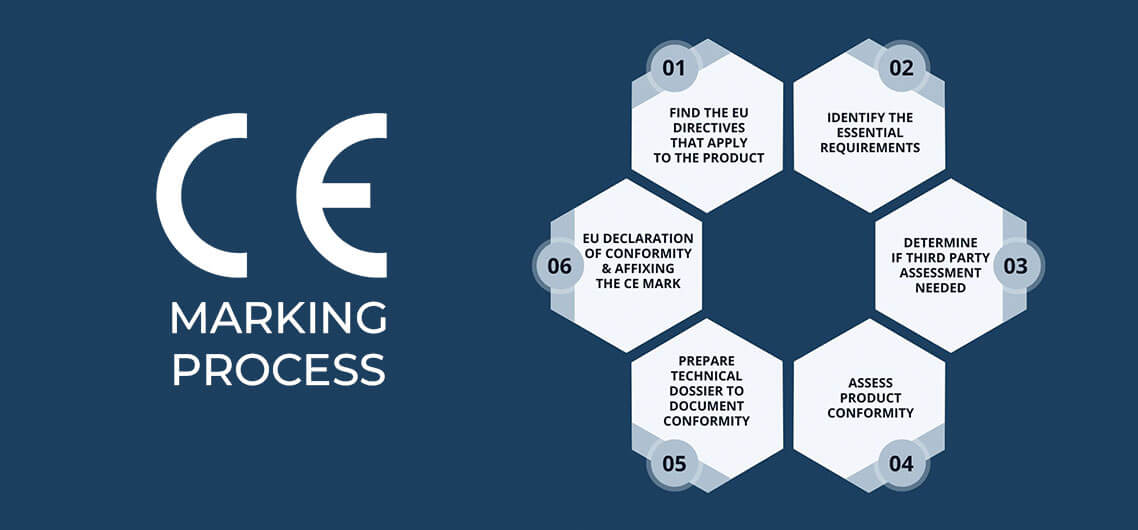

The CE mark certification process

Obtaining the CE mark for a medical device involves a comprehensive certification process. The process begins with determining the appropriate classification of the device based on its intended use and potential risks. Medical devices are classified into four categories: Class I, Class IIa, Class IIb, and Class III, with increasing levels of regulatory scrutiny.

Once the device is classified, the manufacturer must compile technical documentation that demonstrates compliance with the relevant requirements. This documentation includes information on the device’s design, manufacturing processes, and performance characteristics. It also includes a risk assessment and a summary of clinical data, if applicable.

After compiling the technical documentation, the manufacturer must select a Notified Body to carry out the conformity assessment. Notified Bodies are organizations designated by European Union member states to assess the conformity of medical devices. They evaluate the technical documentation and conduct audits and tests to ensure compliance with the applicable requirements.

If the Notified Body determines that the device meets the requirements, they issue a certificate that allows the manufacturer to affix the CE mark. This certificate is valid for a specified period and must be renewed to maintain the CE mark.

Understanding the requirements for CE marking medical devices

To obtain the CE mark, medical devices must comply with the essential requirements set out in the MDD or the MDR. These requirements cover a wide range of aspects, including design and manufacturing, risk management, clinical evaluation, labeling, and post-market surveillance.

Design and manufacturing requirements ensure that medical devices are produced in a controlled environment and meet the necessary quality standards. This includes establishing and maintaining a quality management system, conducting risk management activities, and implementing appropriate manufacturing processes.

Risk management:

Risk management is a critical aspect of CE marking. Manufacturers must identify and evaluate the risks associated with their devices and implement measures to mitigate those risks. This includes designing devices with safety features, providing instructions for use, and conducting post-market surveillance to monitor and address any potential issues.

Clinical evaluation

Clinical evaluation is necessary to demonstrate the safety and performance of medical devices. Manufacturers must gather and evaluate clinical data to support the claims made about their devices. This data can come from clinical investigations, published literature, or post-market surveillance.

Labeling requirements

Labeling requirements ensure that medical devices are properly identified and provide users with the necessary information for safe and effective use. Labels must include essential information such as the device’s intended purpose, instructions for use, and any warnings or contraindications.

Post-market surveillance

Post-market surveillance is an ongoing process that involves monitoring the safety and performance of medical devices once they are on the market. Manufacturers must establish procedures for reporting and investigating adverse events and take appropriate corrective and preventive actions.

Role of notified bodies in CE marking

Notified bodies play a crucial role in the CE marking process, particularly for products that fall under directives requiring independent conformity assessment. These are organizations designated by EU member states and authorized to assess whether a product meets relevant safety, health, and environmental protection standards. Their involvement is essential when self-declaration is not sufficient, typically for high-risk products such as medical devices, pressure equipment, or machinery.

The notified body evaluates technical documentation, conducts audits, and may perform testing to verify conformity. Upon successful assessment, they issue a certificate allowing the manufacturer to affix the CE mark. The identification number of the notified body must also accompany the CE mark if their involvement was required. This process ensures that only compliant and safe products enter the EU market, thereby maintaining consumer safety and regulatory standards. Ultimately, notified bodies act as a key checkpoint in upholding the integrity of the CE marking system.

Documentation and technical file compilation

Documentation and technical file compilation are essential components of the CE marking process. The technical file serves as evidence that a product complies with the relevant EU directives and regulations. It must be prepared by the manufacturer before the product is placed on the market and kept available for inspection by authorities for up to 10 years.

The technical file typically includes a general product description, design and manufacturing drawings, risk assessments, test reports, details of compliance with harmonized standards, and a declaration of conformity. For certain products, it may also include reports from notified bodies or details of quality control systems.

Accurate and complete documentation ensures transparency, traceability, and accountability. It also facilitates easier market access within the European Economic Area. Proper compilation not only demonstrates due diligence but also supports legal defense in case of product-related incidents or disputes. Maintaining an up-to-date technical file is a legal requirement and a best practice in product compliance.

Common challenges in obtaining CE mark certification

Obtaining CE mark certification can be a complex and challenging process for medical device manufacturers. One common challenge is understanding and interpreting the regulatory requirements. The MDD and the MDR are extensive documents with detailed requirements that can be difficult to navigate without expert guidance.

Another challenge is compiling the necessary technical documentation. Manufacturers must gather and organize a vast amount of information, including design drawings, risk assessments, clinical data, and manufacturing records. This task requires meticulous attention to detail and a comprehensive understanding of the requirements.

Selecting the right Notified Body is also crucial for a successful CE mark certification. Notified Bodies have different areas of expertise and resources, and their assessment processes may vary. Manufacturers must carefully evaluate and choose a Notified Body that is best suited to their device and business needs.

Finally, keeping up with the evolving regulatory landscape can be a challenge. The medical device industry is constantly changing, and new regulations and standards are regularly introduced. Manufacturers must stay informed and ensure their devices remain compliant with the latest requirements.

Tips for preparing your medical device for CE marking

Preparing your medical device for CE marking requires careful planning and attention to detail. Here are some tips to help you navigate the process successfully:

1. Start early: CE mark certification can be a time-consuming process. Begin planning and preparing well in advance to allow for any unexpected delays or challenges.

2. Seek expert guidance: Working with a knowledgeable consultant or regulatory expert can greatly simplify the CE mark certification process. They can provide valuable insights and help you navigate the regulatory requirements.

3. Conduct a thorough risk assessment: Identify and evaluate all potential risks associated with your medical device. Implement appropriate measures to mitigate these risks and ensure the safety of your device.

4. Establish a robust quality management system: Implement a quality management system that complies with the relevant standards, such as ISO 13485. This system will help ensure that your device is manufactured consistently and meets the necessary quality requirements.

5. Gather and evaluate clinical data: Collect relevant clinical data to support the safety and performance claims of your device. This data can come from clinical investigations, published literature, or post-market surveillance.

6. Keep up with regulatory updates: Stay informed about the latest regulatory developments and requirements. Regularly review and update your device’s technical documentation to ensure ongoing compliance.

By following these tips and working with experienced professionals, you can streamline the CE mark certification process and ensure the successful entry of your medical device into the European market.

CE mark for in vitro diagnostic medical devices (IVDs)

In vitro diagnostic medical devices (IVDs) play a crucial role in disease diagnosis and patient management. These devices, such as test kits and laboratory equipment, are subject to specific requirements for CE mark certification.

IVDs are classified into four different categories based on their intended use, risk profile, and complexity. The classification determines the level of regulatory scrutiny and the type of conformity assessment required.

For low-risk IVDs, manufacturers can self-declare conformity and affix the CE mark without the involvement of a Notified Body. These devices are subject to general safety and performance requirements, and manufacturers must compile technical documentation to demonstrate compliance.

Higher-risk IVDs, such as those used in genetic testing or blood transfusion compatibility testing, require the involvement of a Notified Body. The Notified Body assesses the technical documentation and conducts audits and tests to ensure compliance with the applicable requirements.

It is important for manufacturers of IVDs to understand the specific requirements and standards applicable to their devices. Working with experts who specialize in IVD CE mark certification can help ensure compliance and expedite the certification process.

CE mark for software as a medical device (SaMD)

With the rapid advancement of digital health technologies, software is increasingly being used as a medical device. Software as a medical device (SaMD) refers to software intended to be used for medical purposes, such as diagnosis, treatment, or monitoring.

SaMD is subject to specific requirements for CE mark certification. The classification of SaMD depends on factors such as the intended use, the risk to patients, and the criticality of the information provided by the software.

Low-risk SaMD, such as mobile health apps for general wellness or self-care, may not require the involvement of a Notified Body. Manufacturers can self-declare conformity and affix the CE mark based on the general safety and performance requirements.

Higher-risk SaMD, such as software used for the diagnosis or monitoring of serious medical conditions, typically require the involvement of a Notified Body. The Notified Body assesses the technical documentation and verifies the software’s conformity with the applicable requirements.

Manufacturers of SaMD must ensure that their software meets the necessary cybersecurity and data protection requirements. They must also establish procedures for software updates and post-market surveillance to address any potential risks or issues that may arise.

Working with experts who specialize in SaMD CE mark certification can help manufacturers navigate the unique challenges associated with software as a medical device and ensure compliance with the regulatory requirements.

CE mark for medical devices post-Brexit

With the United Kingdom’s withdrawal from the European Union, there have been changes to the CE mark requirements for medical devices sold in the UK market. The UK has introduced its own regulatory framework, known as the UK Conformity Assessed (UKCA) mark, which will replace the CE mark in most cases.

Medical devices placed on the UK market must now bear the UKCA mark instead of the CE mark. Manufacturers must ensure that their devices meet the new UK regulatory requirements and obtain UKCA certification from a UK Approved Body.

However, for medical devices sold in the European Union, the CE mark continues to be the applicable certification. Manufacturers must comply with the EU MDR or the MDD and work with a European Notified Body to obtain the CE mark.

It is important for manufacturers to understand the specific requirements for the UK market and ensure compliance with both the CE mark and the UKCA mark, depending on their target markets.

Upcoming changes in EU CE marking regulations

Significant changes to EU CE marking regulations are on the horizon for 2024–2025, focusing on stronger product safety, greater sustainability, and smarter digital integration. Here’s what’s coming:

- General Product Safety Regulation (GPSR): Coming into force on December 13, 2024, the new GPSR (EU 2023/988) replaces the old directive with tougher requirements for manufacturers and importers. Expect more thorough risk assessments, regular product testing, and improved traceability—all aimed at better protecting consumers.

- Cyber Resilience Act (CRA): Expected in late 2024, the CRA will make CE marking mandatory for digital and IoT products. It introduces key cybersecurity standards, with a three-year window to get fully compliant.

- Ecodesign for Sustainable Products Regulation (ESPR): Set for mid-2024, this regulation widens ecodesign rules to cover more products. It also brings in digital product passports to make sustainability and compliance more transparent.

- Construction Products Regulation (CPR) 2024/3110: Effective January 7, 2025, this update enhances CE marking for construction materials, focusing on environmental impact and digital clarity.

Manufacturers should start preparing now to stay ahead of the curve.

Transition timelines under MDR and IVDR

The European Union has extended the transition timelines for the Medical Devices Regulation (MDR) and In Vitro Diagnostic Medical Devices Regulation (IVDR) to support a smoother implementation. For MDR, devices certified under the old Medical Device Directive (MDD) can now remain on the market until December 31, 2027, or 2028, depending on their risk class. This extension gives manufacturers more time to comply with the stricter MDR requirements, including clinical evaluation and post-market surveillance.

Similarly, the IVDR transition period has been staggered based on device classification. Lower-risk devices have until 2028, while higher-risk devices must comply sooner. These extensions aim to prevent disruptions in the supply of essential medical and diagnostic products across the EU while maintaining patient safety and regulatory compliance. Manufacturers must use this time effectively to update technical documentation, obtain notified body certification, and ensure full readiness before the new deadlines

Preparing for evolving EU compliance standards

With major changes to EU compliance standards on the horizon, manufacturers must take proactive steps to stay ahead. Upcoming regulations like the General Product Safety Regulation (GPSR), Cyber Resilience Act (CRA), and the Ecodesign for Sustainable Products Regulation (ESPR) emphasize greater accountability, sustainability, and digital transparency. To prepare, companies should review their current product portfolios, assess gaps against new requirements, and begin updating technical documentation and risk assessments. Engaging with notified bodies early and investing in staff training will help navigate complex regulatory shifts. Digital tools such as product passports and traceability systems should also be explored to meet future demands. Staying informed and adaptive is key—not just to maintain CE marking, but to ensure safe, sustainable, and competitive access to the EU market.

Conclusion: Staying ahead in the industry with CE mark certification

In the competitive and highly regulated medical device industry, obtaining the CE mark is crucial for success. The CE mark demonstrates compliance with the necessary safety, health, and environmental protection requirements and allows manufacturers to access the lucrative European market.

To obtain the CE mark, manufacturers must navigate a comprehensive certification process and ensure compliance with the applicable requirements. This involves understanding the regulatory landscape, compiling technical documentation, and working with a Notified Body. It also requires ongoing compliance with the evolving regulatory requirements and staying informed about the latest developments.

By following best practices, seeking expert guidance, and staying proactive, medical device manufacturers can successfully obtain the CE mark and stay ahead in the industry. The CE mark certification process can be complex, but with the right knowledge and support, manufacturers can ensure the safety and effectiveness of their devices and unlock new opportunities in the European market.

So, if you’re a medical device manufacturer looking to stay ahead in the industry, don’t underestimate the importance of the CE mark. Reach out to our team of experts today and let us guide you through the process, ensuring compliance and success in this highly regulated market.