“Stringent approval procedures controlling the medical devices manufactured, distributed, sold and imported require testing by approved laboratories. When it comes to active medical devices these requirements are complied with standard family IEC 60601.”

Risk Management of Active Medical Device need to be prepared in accordance with requirements of ISO 14971 and IEC 60601-1. In case of active medical devices or as per IEC 60601 standard we can say MEDICAL ELECTRICAL EQUIPMENT (MEDICAL Equipment)/MEDICAL ELECTRICAL SYSTEM (MEDICAL System), Risk Management for medical device shall be carried out with known and foreseeable hazards associated with the medical devices in both normal and fault conditions. It shall also include “Single Fault Conditions” of Medical Devices as per IEC 60601-1 but it shall not be limited to it.

One important thing that shall be kept in mind is that, requirements of standards of Active Medical Devices are complied with, then residual risks addressed by these requirements shall be presumed to be acceptable or an Objective Evidence to the contrary shall be available to prove the information which is accepted as residual risk. These Objective Evidence could be anything based on facts obtained through observation, measurement, test or other means.

What is Essential Performance? Do we need to mention it in Risk Management of an Active Medical Device?

The functions which are Essential Performance Requirements of the ME Equipment/System shall be identified by the manufacturer in Risk Management Report. Essential Performance of the ME Equipment/System can be determined by the Manufacturer in accordance with its policy for Risk Acceptability.

It also helps to determine a component with High-Integrity Characteristics and to find out the characteristics that are required to maintain basic safety or performance.

Suggested Read:

The Importance of Risk Management for Medical Device Manufacturers

Humidity

Humidity testing requirements from IEC 60601-1 Edition 2.0 have been reestablished.

Documentation

A number of documentation requirements for user manuals and instructions for use (IFU) have been added. In addition, electronic versions of all accompanying documentation must apply the usability engineering process as covered in the collateral standard, IEC 60601-1-6, Usability, in determining what information must be presented.

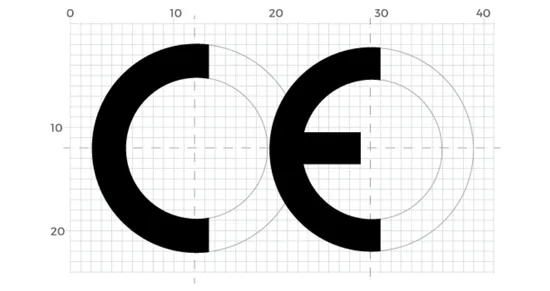

Marking and Labelling

Equipment and accessory labelling must include a unique serial number or lot batch identifier, date of manufacturer or “use-by” date, and manufacturer contact information.

Explore Medical Device Labelling Service

Electrical Hazards

There are a number of requirements related to protections from potential electrical hazards, including defibrillation protection, protective earth and creepage and clearance distances. There are new limits for leakage current testing for functional earth connections. Protective earth testing with a power supply cord is required for devices equipped with appliance inlets. Permanently installed equipment must include a power lockout device if reconnection presents a potential hazard to a user.

Mechanical Hazards

Testing for mechanical hazards related to instability and mobile equipment has been modified to include functional testing.

Temperature Testing

For applied parts, temperature limits have been clarified. For overflow, equipment must be designed to ensure that basic safety and essential performance are maintained at all times.

Why IEC 60601-1?

Standard IEC 60601-1 can be used as a tool during the Risk Management Process for medical devices. Conditions or Faults mentioned in this standard cab be used as an inputs/hazards.

What is PEMS? Why Risk Management of Medical devices for PEMS?

For Programmable Electrical Medical Systems (PEMS), it requires application of Risk Management Process in accordance with ISO 14971. It might be difficult to show the correctness of software and complexity of hardware. That is why PEMS has to be performed within a Risk Management Process.

Is PMS Validation important for an Active Medical Device?

PEMS Validation also has to be performed which can be considered as the final stage of PEMS Development Life Cycle. Validation is important for PEMS because unexpected interactions between functions might occur that can only be discovered by PEMS Validation.

Suggested Read:

Quantification of Benefit – Risk Analysis

Usability & Risk Management of Medical Devices?

Usability Engineering processes are nothing but assessment and mitigation of Risks caused by Usability problems associated with the correct use & use errors, i.e., normal use. It can be used to identify but does not assess or mitigate risks associated with abnormal use.

The criteria for establishing the Risk Acceptability can be established by the Usability Validation Plan of the Active Medical Device.