In the regulated healthcare environment, ensuring the safety and effectiveness of medical devices is a requirement. For manufacturers of Class A and B medical devices, obtaining ISO 13485 certification is a critical step toward proving their commitment to quality, patient safety, and adherence to international standards. With regulatory scrutiny increasing, understanding what is ISO 13485 and its application to Class A and B medical devices is essential to maintaining compliance and market trust.

Introduction to ISO 13485 Certification

ISO 13485 is the internationally recognized standard that specifies requirements for a quality management system for medical devices. It helps organizations consistently meet regulatory requirements for medical devices and deliver products that are safe for their intended use.

Developed by the International Organization for Standardization, the ISO 13485 standard is designed specifically for the medical device industry, addressing both design and manufacturing. Unlike other standards, ISO 13485 for medical devices places a strong emphasis on risk management, controlled production, and documentation controls.

Why ISO 13485 is Crucial for Class A and B Devices

Manufacturers of Class A and B medical devices face unique compliance obligations. Class A devices, such as surgical gloves or tongue depressors, are considered low-risk, while Class B medical devices, including infusion pumps or contact lenses, are considered moderate-risk. However, both must meet core quality and safety requirements.

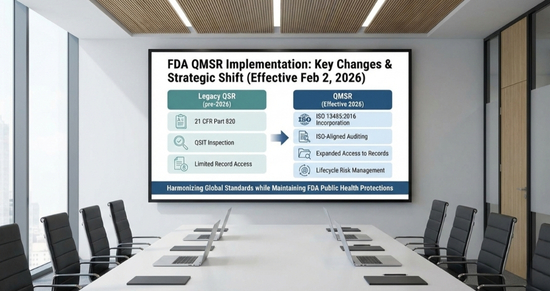

An ISO 13485 certificate demonstrates that your organization has implemented a compliant QMS (Quality Management System) that meets global expectations. This is especially important for manufacturers seeking market entry in countries that demand certification from a Notified Body, including India’s CDSCO, the EU under MDR, and Canada’s MDSAP.

According to the CDSCO guidelines, Class A and B devices must be registered using Form MD-3, which may involve quality system documentation aligned with ISO 13485 requirements.

Classification of Medical Devices: Class A and B Explained

Understanding medical device classification is crucial for manufacturers to apply the correct regulatory approach. Devices are generally classified into Class A, B, C, or D depending on their risk level.

Class A Medical Devices

These are low-risk devices such as stethoscopes, thermometers, or surgical dressings. Though simpler in design, they must still conform to basic medical device regulations, including documentation, complaint handling, and post-market surveillance.

Class B Medical Devices

These low-to-moderate risk devices, such as dental curing lights, suction machines, or contact lenses, require more robust quality processes. For Class B medical devices, compliance with ISO 13485 certification involves more rigorous requirements and greater oversight by a notified body or authority.

Proper medical device classification defines your regulatory path and helps avoid compliance issues down the line.

ISO 13485 Certification Process for Class A & B Devices

Implementing the ISO 13485 certification process can seem complex, especially for small or mid-sized manufacturers. However, understanding each stage simplifies your journey.

Step-by-Step Process:

- Gap Assessment: Evaluate current practices against ISO 13485 requirements.

- Documentation Development: Create or revise documents, such as SOPs, device master records, and risk files.

- QMS Implementation: Establish a functioning medical device QMS across departments.

- Internal Audit: Identify areas for improvement before formal assessment.

- Management Review: Ensure leadership involvement in quality performance.

- Certification Audit: A notified body evaluates your system.

- Ongoing Documents: Maintain compliance through updates, audits, and CAPA systems.

Global acceptance of the ISO 13485 standard means this certification lays the foundation for other approvals, including CE Marking, MDSAP, and Health Canada licensing.

Key ISO 13485 Requirements Relevant to Class A & B Devices

The ISO 13485 requirements are both broad and deep, focusing on risk management, design control, and product traceability. For Class A and B medical devices, the following areas are particularly important:

- Design & Development Controls: Especially critical for Class B medical device manufacturing.

- Risk Management: In line with ISO 14971, essential from concept to post-market surveillance.

- Sterility and Cleanliness: Necessary for both reusable and disposable devices.

- Supplier Controls: All third-party vendors must meet quality standards.

- Documentation and Traceability: Clear, current, and accessible ongoing documents that reflect all product changes.

By aligning your systems with these ISO 13485 medical devices standards, you ensure safer products and smoother regulatory approvals.

The Importance of Implementing a QMS Aligned with ISO 13485

An effective Medical Device Quality Management System helps comply with the law and also improves product consistency, customer satisfaction, and operational efficiency.

For Class A and B medical devices, a solid QMS system ensures that you can:

- Demonstrate compliance during inspections or audits.

- Reduce product recalls and field failures.

- Shorten time-to-market for new devices.

- Enhance documentation for CE marking or CDSCO registration.

Implementing a QMS aligned with ISO 13485 compliance is a legal necessity and also a strategic business investment.

Maven Profcon Services LLP: Your Trusted Partner for ISO 13485 Certification and Regulatory Compliance

Understanding medical device regulations can be complex, but Maven simplifies this process. As CE certification consultants and compliance specialists, we guide manufacturers through every stage, from medical device classification to final audit.

Here’s how Maven supports you:

- End-to-end assistance in setting up a compliant QMS system.

- Preparing all required ongoing documents for audits and regulatory filings.

- Internal audits and gap assessments for Class A and B medical devices.

- Guidance on CDSCO documentation, including Form MD 7.

- Cross-border readiness: support for CE Marking, UKCA, and MDSAP aligned with ISO 13485 compliance.

Our expertise enables you to deliver safe and compliant devices to global markets on time, every time.

Suggested Read: EU MDR Classification of Medical Devices

Conclusion

For manufacturers of Class A and B medical devices, obtaining ISO 13485 certification is a gateway to quality, global trust, and patient safety. By implementing a robust quality management system for medical devices, organizations can stay ahead in a competitive and regulated industry.

With experts like Maven by your side, completing the ISO 13485 certification process becomes a structured, achievable goal. Let us help you meet international ISO 13485 requirements, stay compliant, and build safer products consistently.

References

1. CDSCO Registration Process

2. The Necessity of ISO 13485 Certification for Class A and B Medical Devices

3. Regulatory pathway to be followed for the Medical Device from its development to commercialisation under Medical Devices Rules, 2017