Introduction

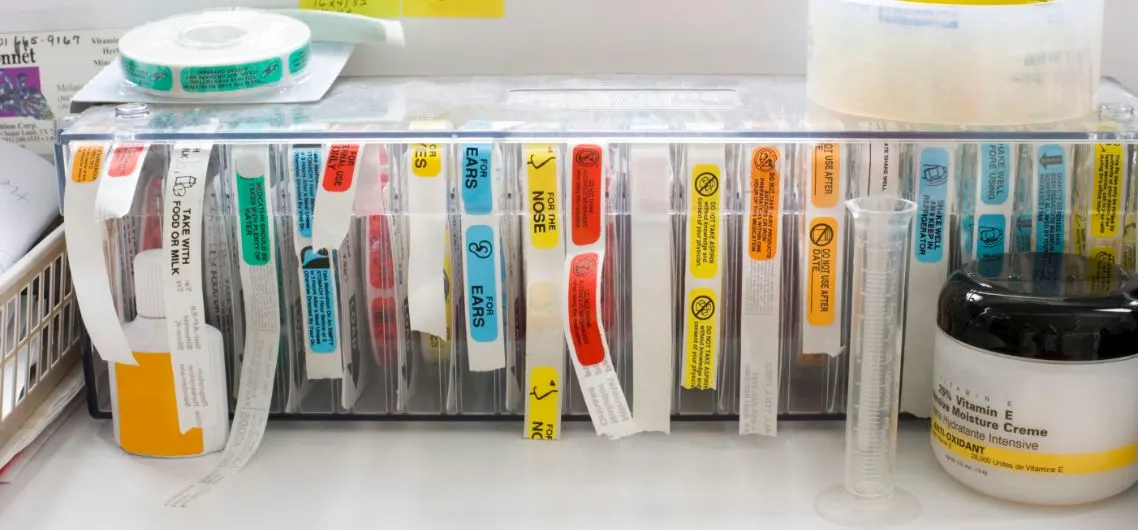

When it comes to medical devices, what’s on the label matters just as much as what’s in the package. Every detail, from the device name to safety instructions, must be correct, transparent, and compliant with stringent global regulations. Mistakes can lead to regulatory penalties, product recalls, or patient harm. This is why compliance with medical device labeling is essential.

At Maven, we help medical device manufacturers meet the highest labeling standards and avoid compliance issues. With our support, manufacturers can effectively address complex medical device labeling regulations, protect patient safety, and confidently enter global markets.

Importance of Accurate Labeling for Patient Safety

Accurate medical labels play a direct role in how medical devices are used, handled, and understood. They provide crucial information such as:

- Intended use

- Warnings and precautions

- Sterility details

- Expiry dates

- Manufacturer contact info

- Traceability codes

Correct labeling empowers healthcare professionals and patients to make informed decisions. It also ensures that devices are used as intended, increasing safety and reducing risk. Medical device labeling compliance isn’t just about avoiding fines; it’s about saving lives.

Understanding Medical Device Labeling Requirements

Complying with global medical device labeling standards requires an understanding of regional regulations and harmonized guidelines. Each market has its own set of rules that manufacturers must follow.

Key Global Regulations Governing Labeling

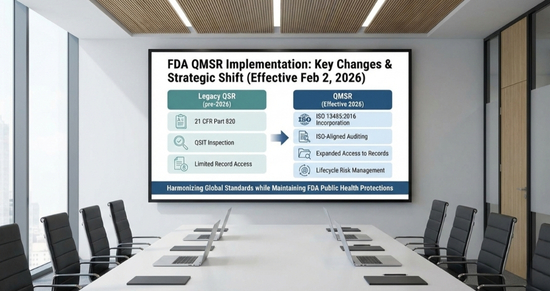

FDA (21 CFR Part 801, 830, UDI Requirements)

The FDA device labeling regulations fall under 21 CFR Part 801, which mandates labeling requirements for device identity, directions for use, and warnings. In addition:

- 21 CFR Part 830 introduces the Unique Device Identification (UDI) system to improve device tracking and post-market surveillance.

- UDI must appear in both human-readable and machine-readable formats.

- Device labels must include a Device Identifier (DI) and a Production Identifier (PI).

The FDA also requires electronic labeling compliance for certain classes of devices, especially those used in healthcare institutions.

EU MDR (Medical Device Regulation 2017/745)

The EU MDR 2017/745 introduced comprehensive changes to how medical devices are labeled in Europe. Under this regulation:

- Labels must be translated into the official language of each country where the product is sold.

- Devices must include the UDI system and a Basic UDI-DI for documentation purposes.

- Specific icons, warnings, and details like “single-use” or “sterilized” must be marked.

Failure to comply with EU MDR can lead to import bans, market access denial, and regulatory action from the European Commission.

ISO 15223-1

ISO 15223-1 provides standardized symbols for healthcare labels, helping manufacturers create universally understandable labeling. These symbols reduce language barriers and improve clarity. The standard is beneficial for:

- Surgical instruments

- Implants

- Diagnostic devices

Using approved symbols is a best practice, and it’s a requirement in many jurisdictions to meet medical device labeling standards.

Common Regulatory Pitfalls in Medical Device Labeling

Labeling mistakes aren’t always obvious. Even minor oversights can lead to regulatory violations. Common pitfalls include:

- Missing critical information like expiration dates or warnings

- Inconsistent information between primary and secondary packaging

- Outdated or incorrect regulatory symbols

- Lack of language translations for international markets

- Non-compliance with UDI formatting rules

- Failure to reflect label updates after design or manufacturing changes

These errors can trigger audits, delay product launches, or cause recalls. At Maven, we proactively guide clients in avoiding these risks by aligning labeling strategies with updated medical device regulations across all target markets.

Medical Device Packaging and Labeling Compliance

Achieving full compliance in packaging and labeling is a regulatory requirement and a critical part of delivering safe and effective medical devices to patients. Proper packaging works hand-in-hand with accurate medical device labeling to ensure that devices maintain their integrity from production to the point of use.

Importance of Compliant Packaging in Medical Devices

Packaging is an extension of labeling; it must protect the device and communicate critical information. Non-compliant packaging can compromise sterility or usability, even if the medical labels are correct.

Packaging also plays a vital role in user safety and traceability. Poorly designed packages can lead to damaged products or incorrect use, especially in high-pressure environments like hospitals.

Packaging Requirements Under FDA, EU MDR, and ISO 11607

- The FDA mandates packaging systems that ensure the device’s sterility and usability throughout its lifecycle.

- EU MDR requires devices to be tamper-proof, sterile (when applicable), and traceable via UDI on the package.

- ISO 11607 defines validation processes for packaging used with terminally sterilized devices. It outlines requirements for package integrity, strength, and sealing performance.

These regulations aim to ensure that patients receive sterile, safe, and functional products every time.

Common Errors in Packaging and Labeling

Frequent issues in packaging include:

- Incorrect label placement leading to barcode scanning errors

- Insufficient instructions for opening packages without contaminating the contents

- Weak seals that compromise sterility

- Lack of tamper-evidence

Ensuring Sterility and Tamper-Evidence in Packaging

Sterile barrier systems must be validated and tested for durability, shelf life, and real-world conditions. Tamper-evidence mechanisms like sealed closures or breakable tabs are essential to ensure the product hasn’t been compromised during transport or storage.

Best Practices for Ensuring Medical Device Labeling Compliance

Achieving long-term medical device labeling compliancemedical device labeling compliance requires consistent systems and trained personnel. Recommended best practices include:

- Conducting regular internal audits of labels and packaging

- Implementing global change control systems for label updates

- Using standardized label templates aligned with ISO 15223-1

- Keeping digital archives for label versions and approvals

- Localizing labels for each regional market

- Including regulatory affairs experts in the labeling process

- Monitoring post-market feedback for label-related issues

The Role of Technology in Medical Device Labeling Compliance

Technology is a key enabler of accuracy, efficiency, and traceability in labeling. Automated labeling systems reduce human error, ensure consistency, and maintain audit trails.

At Maven, we integrate technology to help clients:

- Generate compliant labels using region-specific templates

- Auto-populate UDI and serial data

- Validate formatting, font size, and layout

- Track label changes and approvals in real-time

- Sync labeling data with product lifecycle and quality systems

Our digital tools help manufacturers scale operations while staying fully aligned with medical device labeling regulations in all markets.

Conclusion

In the highly regulated world of medical devices, even small labeling mistakes can have major consequences. As regulations evolve, the need for precise, standardized, and compliant medical device labeling becomes even more critical.

By understanding global requirements like FDA (21 CFR), EU MDR, and ISO 15223-1 and following best practices in labeling and packaging, manufacturers can avoid regulatory pitfalls and build trust with healthcare professionals and patients.

Maven helps medical device companies stay ahead by offering tailored guidance. Our medical device regulatory consultants simplify compliance, reduce risks, and accelerate time-to-market, ensuring our clients deliver safe and reliable products efficiently. With our help, manufacturers can reduce risk, improve safety, and confidently bring their products to market, all while meeting the highest medical device labeling standards worldwide.

References